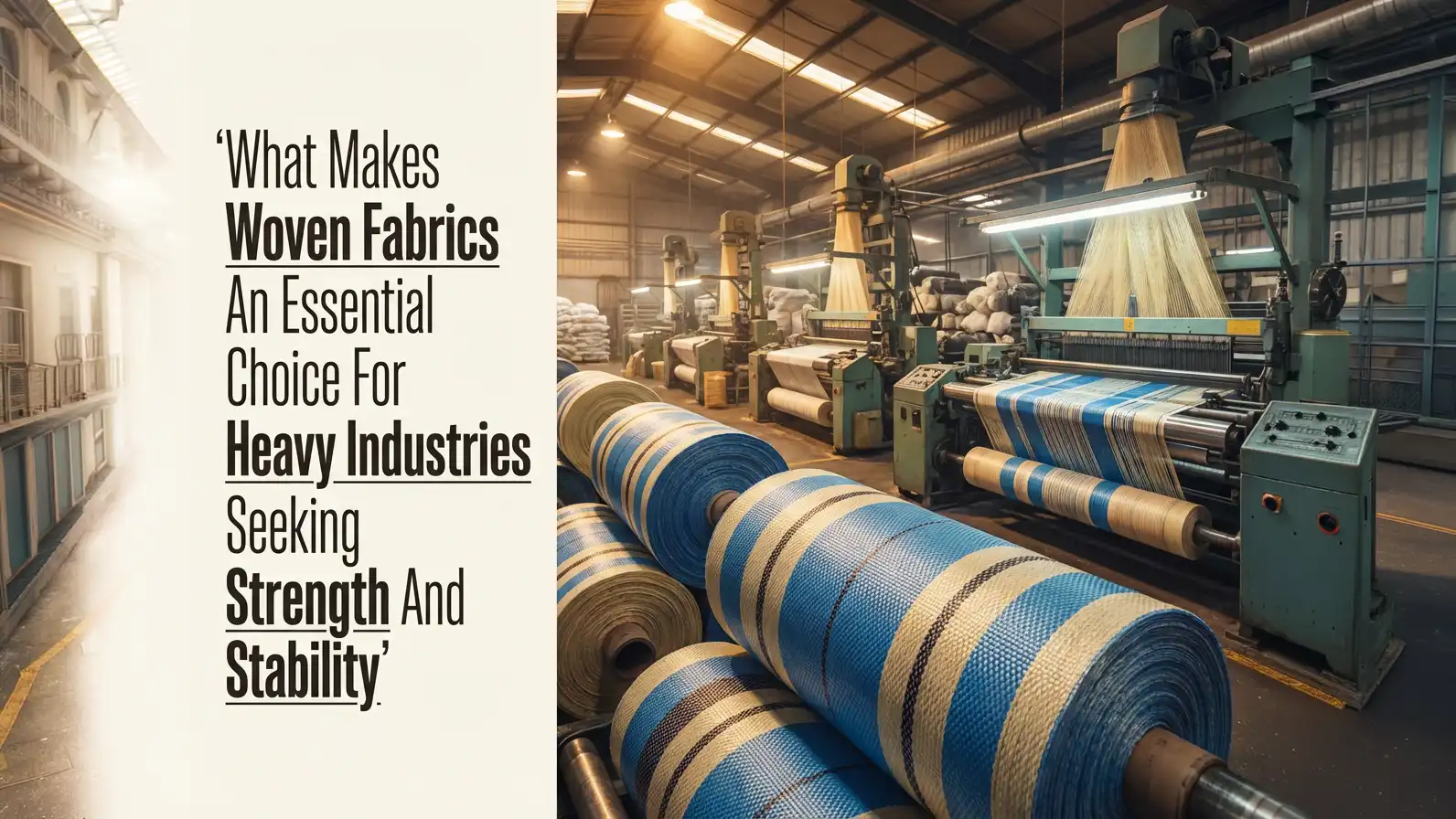

What Makes Woven Fabrics an Essential Choice for Heavy Industries Seeking Strength and Stability

Heavy industries don’t simply need packaging or covering materials — they need structural support systems that can survive pressure, movement, moisture, sunlight, stacking, loading, and long-term outdoor exposure. This is why HDPE Woven Fabric has become one of the most dependable industrial materials used across manufacturing, logistics, agriculture, mining, and construction. And at the center of this reliability is Ashoka Poly Laminators, a name that has consistently supplied woven fabrics engineered for durability, stability, and real-world performance.

When industries select a material for heavy-duty applications, failure is not an option. One tear can disrupt an operation. One weak batch can halt production. One unreliable supplier can damage a brand’s reputation. That is why woven fabrics built with engineering discipline, material science, and consistent lamination quality are preferred — and that’s exactly what businesses trust from Ashoka Poly Laminators.

Why Heavy Industries Prefer Structured Fabrics Over Lightweight Alternatives

Heavy industry supply chains are intense. Materials are dragged, lifted, tied, stacked, and exposed to unpredictable weather conditions. In such environments, flexibility and strength must work together. HDPE Woven Fabric delivers this combination better than many traditional materials.

Its cross-weave structure distributes stress evenly.

Its lamination improves weather resistance.

Its lightweight nature allows easy handling without compromising strength.

These qualities are why the fabric has become essential for covers, wrapping, bundling, construction site protection, truck loading, and industrial storage.

The woven structure acts almost like armor — flexible enough to bend but strong enough to absorb pressure without tearing. Ashoka Poly Laminators further enhances this reliability through consistent weaving patterns and controlled GSM levels that match industry requirements.

How Woven Fabrics Deliver Structural Stability in Demanding Environments

Industries don’t operate in controlled environments. Dust, sunlight, rain, abrasion, and friction are daily realities. HDPE Woven Fabric is designed to withstand these challenges by using high-density polyethylene strands woven tightly together.

This weaving provides:

- Superior tensile strength

- Impact resistance under repeated load

- Dimensional stability

- Long-term durability in outdoor use

- Dependable reinforcement for laminated structures

Ashoka Poly Laminators adds value through precision looms, stable weaving tension, and quality checks that prevent weak spots. When industries choose their woven materials, they want fabrics that behave consistently, and this is exactly what APL ensures through its disciplined manufacturing process.

Every roll is produced with purpose — to perform under stress.

Why HDPE Woven Fabric Became the Backbone of Industrial Protection

When companies choose a protective material, they have three expectations: strength, longevity, and cost efficiency. HDPE Woven Fabric meets all three, making it indispensable for sectors that depend on reliable protection.

Many industries use woven fabrics for:

- Heavy-duty packaging

- Industrial coverings

- Moisture-resistant wrapping

- Temporary shelters

- Truck and trailer covers

- Construction barricades

- Agricultural ground covers

Each application demands a material that won’t fail when exposed to repeated tension or unpredictable weather. Businesses trust Ashoka Poly Laminators because their woven fabrics consistently meet these expectations across diverse industrial scenarios.

What Sets Ashoka Poly Laminators Apart in Woven Fabric Manufacturing

In heavy industries, experience matters. Reliability matters more. And consistency matters most.

Ashoka Poly Laminators produces HDPE Woven Fabric with a deep understanding of how industries use and test these materials. The company focuses on:

- Tight weaving patterns that increase strength

- Uniform lamination for weather resistance

- Stable GSM levels for predictable performance

- High-purity HDPE to prevent premature degradation

- Quality control that checks every roll before dispatch

This approach ensures that woven fabrics made by Ashoka Poly Laminators behave the same across every order — strong, predictable, and dependable. Industrial clients rely on this because inconsistent fabric leads to operational risk.

When APL manufactures woven materials, the goal is simple: create industrial-grade performance you can trust.

Why Cheap or Low-Quality Woven Fabrics Fail in Real Industrial Use

Industries that choose low-cost alternatives often face hidden losses. Poor-quality woven fabrics tear under load, delaminate under heat, weaken when exposed to UV rays, or absorb moisture due to poor lamination. These failures become expensive quickly.

Weak materials lead to:

- Damaged goods

- Delays in operations

- Safety hazards for workers

- Loss of customer trust

- More frequent replacements

Businesses working with Ashoka Poly Laminators avoid these issues because the company maintains strict quality parameters that keep each roll consistent. High-quality woven fabrics may cost more upfront, but they save significantly more in long-term performance and reduced downtime.

Strong materials protect operations. Weak materials disrupt them.

How Woven Fabrics Support Modern Industrial Growth

India’s industrial landscape is growing rapidly — more warehouses, more construction sites, more transport routes, and more manufacturing hubs. With this growth comes a demand for materials that can keep up. HDPE Woven Fabric remains one of the most adaptable materials because it suits both traditional and emerging needs.

From old-style grain storage to new-age e-commerce logistics, the applications continue expanding. Ashoka Poly Laminators stays ahead of this demand by producing woven fabrics that combine traditional strength with modern finishing techniques.

As industries grow, their protective materials must evolve — and APL continues to lead that evolution.

Why Reliability in Fabric Quality Builds Industrial Confidence

Heavy industries cannot afford surprises. They need materials that perform the same way every time. This is why many companies depend on HDPE Woven Fabric produced by Ashoka Poly Laminators. The reliability of these fabrics becomes part of the industry’s operational confidence.

When protective materials behave predictably, planning becomes easier.

When covers last longer, costs decrease.

When strength is proven, teams work more efficiently.

This confidence becomes a competitive advantage, especially in sectors where precision and stability matter every day.

Looking for bulk tarpaulin or packaging solutions?

Contact Ashoka Poly Laminators Ltd. – India’s trusted manufacturer for durable, export-quality tarpaulins and retail packaging.

📧 Email: apl@ashokafoam.com

📞 Phone: +91 7078666249